DECARBONISE

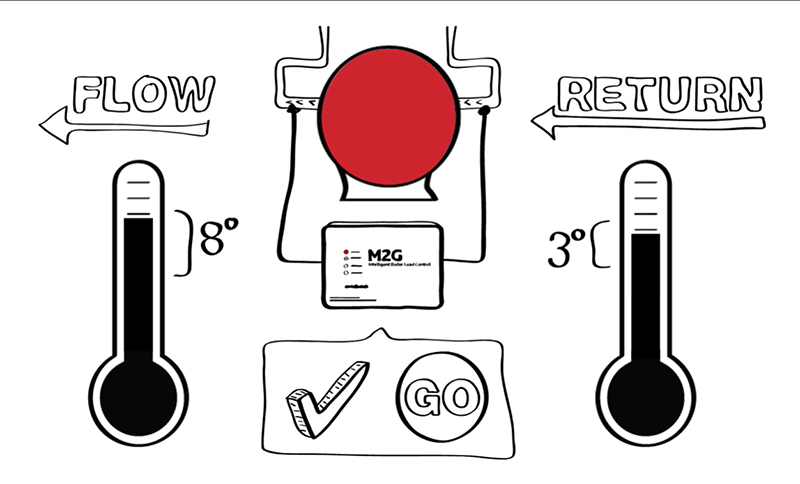

M2G - Intelligent Boiler Load Control

Traditional approaches to boiler management can be outdated

It’s about time things got smart

Boilers are often forgotten, but they’re crucial for business. Keeping a building warm in winter and supplying hot water needs are the basics that continue to cost too much – to both an organisation and to the environment.

Boiler ‘dry cycling‘, the challenge faced by sustainability and energy managers, is universal. Built-in ‘intelligence’ to address that issue is missing in most boilers.

In commercial buildings, 92% of non-electrical consumption is attributed to space heating / hot water. The fundamentals of boiler efficiency are clear: removing dry cycling can contribute a 10-25% saving, more than any other singularly addressed factor.

M2G intelligently identifies instances of boiler dry cycling and immediately inhibits the boiler firing up unnecessarily. Yes, we’re selling a simple concept, but with it we’re helping sustainability and energy managers achieve instant, measurable results and solve an inherent and almost universal boiler issue.

Satisfying the requirements of all your internal and external stakeholders

- Direct and lasting reduction in OPEX

- Demonstrable and immediate savings in gas consumption

- Proven reduction in CO2 contribution

- Non intrusive installation

- No changes to existing set points or plant and no down time

- Maintenance free

- Lifetime support

A return on investment well below the energy solution industry average

EVIDENCE

You don’t have to just

take our word for it

From universities, hospitals and government buildings to shopping centres, corporate HQs and leisure facilities: hear how M2G users are benefitting from this simple approach to carbon management.

SMART

Cloud-connected

carbon management

Sabien’s approach to cloud-connected carbon management involves retrofitting an IoT solution to any existing boilers fitted with the M2G boiler management solution. A dashboard, accessible remotely via mobile or web app instantly displays data on how the boilers are performing, how M2G is optimising energy use, and the associated cost and harmful emission reductions. Unfortunately, boilers aren't typically imbued with intelligence. But smart boilers – and cutting carbon emissions, reducing operating spend and meeting crucial regulatory targets – are smart business.

CONNECTED

A birds eye view of efficiency, cost

savings and carbon reduction

The utilities industry is the most prolific user of internet of things (IoT) endpoints, with around 1.37 billion connected ‘things’ in operation, globally. Amongst those billions of things, are a whole lot of boilers.

Once connected to the internet, data on a boiler’s temperature, energy use, increased efficiency and cost savings can be logged automatically, in real time. Data gathering and analysis can also be extended to the surrounding environment: how well is the building’s boiler plant as a whole performing from an energy efficiency perspective? Where can carbon management be improved? Where can we start realising cost savings with the associated reductions in emissions?

This doesn’t involve ripping out and replacing an old, dumb boiler. It doesn’t involve waiting for an engineer to come out and manually take readings. And it doesn’t involve any of the associated costs.

Idle period per day